History - Asper Engineering

Key Milestones & Dates

Laying the Foundation for Growth

With a vision to revolutionize precision tooling, we began our journey as an importer and distributor of cutting tools. Without in-house production capabilities, our focus was on sourcing high-quality tools to meet industry demands. Through strategic partnerships and a commitment to excellence, we established a solid reputation for delivering reliable solutions.

Adapting to market needs, we cultivated deep industry expertise and built strong customer relationships. This phase was crucial in shaping our long-term vision, laying the foundation for future expansion. By understanding the evolving demands of the machining sector, we positioned ourselves for growth, innovation, and in-house manufacturing excellence.

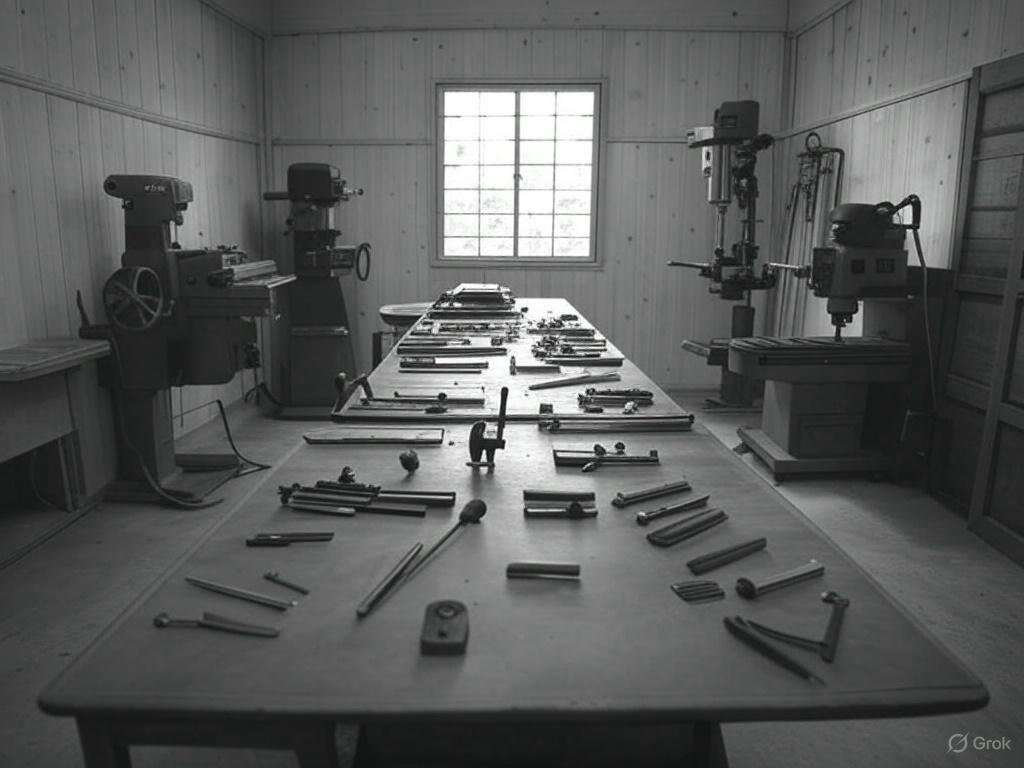

Advancing with In-House Manufacturing

With growing demand and industry expertise, we took a significant step forward by establishing our own tool-making facility. Investing in a manual tool-making machine, we transitioned from import-based sales to in-house manufacturing. This milestone allowed us to enhance product quality, customize solutions, and cater to specific customer needs.

Starting with a small but skilled team of three, we soon expanded our workforce to five, ensuring greater efficiency and production capacity. This phase marked our transformation from a distributor to a manufacturer, paving the way for future advancements in precision tooling.

We go beyond manufacturing by offering high-quality Re-Grinding and Re-Coating services to extend the lifespan and performance of your cutting tools.

Re-Grinding

Re-Coating

These services help our customers maximize their tooling investments while maintaining the highest machining standards.

Advancing with CNC Precision

Continuing our commitment to excellence, we took a major leap by integrating advanced CNC tool-making machines into our production line. This upgrade revolutionized our manufacturing process, allowing us to achieve faster production speeds, higher precision, and zero-defect quality.

With automation and technological advancements, we enhanced our efficiency while maintaining the highest industry standards. This milestone positioned us as a leading provider of precision-engineered tools, ensuring superior performance and reliability for our customers. Looking ahead, we remain dedicated to innovation and excellence in cutting tool solutions.

Revolutionizing Manufacturing with Automation

As part of our long-term vision, we are preparing to expand into robotic machine sales, marketing, and services for manufacturing industries. Our roadmap includes introducing automation-driven solutions that enhance productivity, reduce operational costs, and improve precision in industrial processes.

Rather than setting a fixed timeline, our phased approach will align with industry advancements and customer demands. We will gradually implement robotic solutions, ensuring seamless integration and maximum efficiency for our clients. Our dedication to innovation and smart manufacturing will drive us forward as we shape the future of industrial automation.